S Series: QUINMAX

5 Plunger Pumps

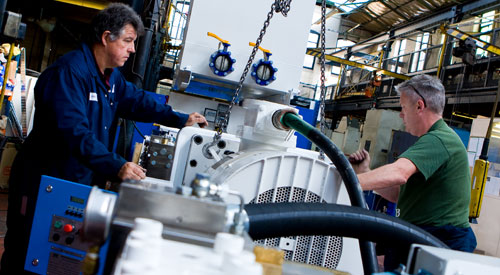

The S Series Quinmax 5 plunger pumps are designed to provide a safe, reliable supply of high-pressure water-based fluids for mining and heavy industrial applications.

Core Values

LOWER

INSTALLED

COST

LOWEST

OPERATING

COST

REDUCED

PROJECT

RISK

High Energy Efficiency

- Variable speed controls using demand-based operation

High Performance

- Innovative design for increased crank speeds and loading.

- Proven volumetric efficiencies up to 98%.

- 40% reduction in fluid velocity reducing hydraulic noise when compared to the Trimax series.

- Fluid end components designed with Computational Fluid Dynamics to maximise efficiency.

- Drained gland well to separate the oil and fluid ends of the pump, to stop contamination.

Maximum Reliability

- Designed for continuous duty, 24/7

Extended Operational Life

- smooth pressure profile, reduces wear and tear on system components (hoses, seals, valves) caused by destructive pressure surges

Compact Footprint

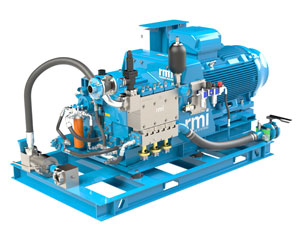

- Compact horizontal 5 plunger design

Technical Data

Application

Longwall Coal Mining and Industrial manufacturing applications including forging, extrusion, rolling, hydrostatics, power generation, industrial cleaning and filtration.

Description

Skid-mounted horizontal five plunger design pumping unit. High-efficiency energy through demand-based control. Remote active performance management through internet to sustain reliability and performance throughout the life of the pump.

Materials

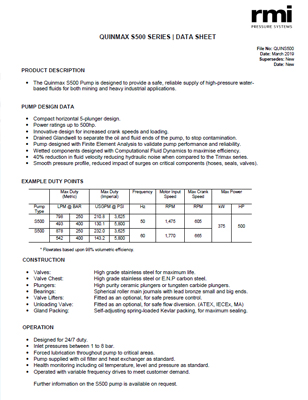

- Valves: High grade stainless steel for maximum life.

- Valve Chest: High grade stainless steel or E.N.P carbon steel.

- Plungers: High purity ceramic plungers or tungsten carbide rams.

- Bearings: Spherical roller main journals with lead bronze small and big ends.

- Valve Lifters: Fitted as an optional, for safe pressure control.

- Unloading Valve: Fitted as an optional, for safe flow diversion. (ATEX, IECEx, MA)

- Gland Packing: Self-adjusting spring-loaded Kevlar packing, for maximum sealing

Configuration

- Pump supplied with oil filter and heat exchanger as standard.

- Health monitoring including oil temperature, level and pressure as standard.

- Operated with variable frequency drives to meet customer demand.

- Network enabled for remote performance management connectivity.

Performance Range

Enhanced flow rated (up to 1168 l/min)

Temperature

Maximum operating temperature 40OC

Power

375kW (500Hp)

Dimensions

| Length | 1255mm (49.4”) |

| Width | 978mm (38.5”) |

| Height | 757 (29.8”) |

Data Sheets

Resources

S Series Solution Overview Brochure

Data Sheet

Case Studies

Case Study

You May Also Be Interested In

S SERIES TRIMAX